We don't think outside the box.

We think around the box.

We don't think outside the box.

We think around the box.

iFD GmbH owns an independent research and development department. This is an important requirement to guarantee a permanent innovation and advancement process for all software systems and add-on components.

Continuous development, active research projects, and ongoing improvement of concepts and products are the guarantee for success for adapted software systems. These software systems represent the perfect logistic solution for multiple national and international customers.

Since the founding of the company in 1990 iFD realized more than 300 cross-industry projects.

The iFD systems are used across all industries in almost every size and characteristics - from classic warehouse management for manual and automated warehouses, to material flow control systems for facilities with high availability requirements, to picking systems using Pick-By-Voice or Pick-By-Light - technology.

The browser-based, modular Warehouse Management System supports all manual and automatic intralogistics processes. With dimensioning logics, the system is suitable for both classic picking warehouses and highly complex automated systems - with batch or wave picking.

The system stands for maximum flexibility, which is particularly evident in individual hardware concepts and the connectivity options of host and subsystems. Smartphones, tablets and wearables can easily be integrated at any technology level. The well thought-out, intuitive operating instructions facilitate quick training and increase the acceptance of the system.

The level of automation in logistics increases continuously. Due to the high investments, it is essential to fully exploit the capacity of your automated system with intelligent controls. Our material flow control is a manufacturer-independent, future-proof solution that offers highest performance, the best routing, flexible interfaces, and free choice of database and operating system.

With the WarehousePilot from iFD, all important system parameters are visualized in an easy and understandable way. An central, browser-based monitoring system - that makes additional SCADA software needles - is used to permanently visualize information about the current system occupancy, active transport orders and cycle states of individual conveyor locations. Adjustments such as closing and opening of selected areas can be done directly through the visualization dialogue.

Increase the performance of your fleet with existing resources. All transports are optimised in a digital order pool, managed and assigned to the forklift fleet in real time. Increase process reliability, avoid empty runs, maximise utilisation and meet target deadlines - the iFD forklift control system supports everything.

The iFD SLS keeps track of utilisation, locations and available equipment at all times. As a result, priorities from orders and processes are reconciled and conflicts are eliminated. Using comprehensive statistics, the system can generate KPIs and provides comprehensive evaluations of productivity, full and empty runs and fleet utilisation.

The connection and control of driverless transport systems (AGV) is also implemented in the iFD-SLS. And our system even goes a step further, as it not only allows the control and optimisation of the manned and unmanned fleet, but also the coordinated control of man and machine in one system.

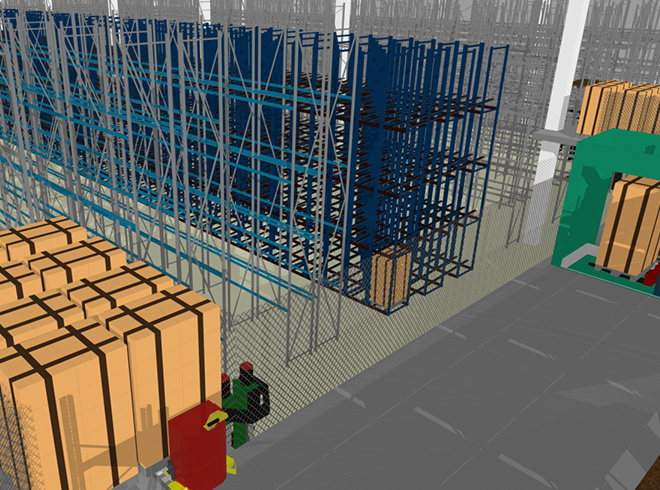

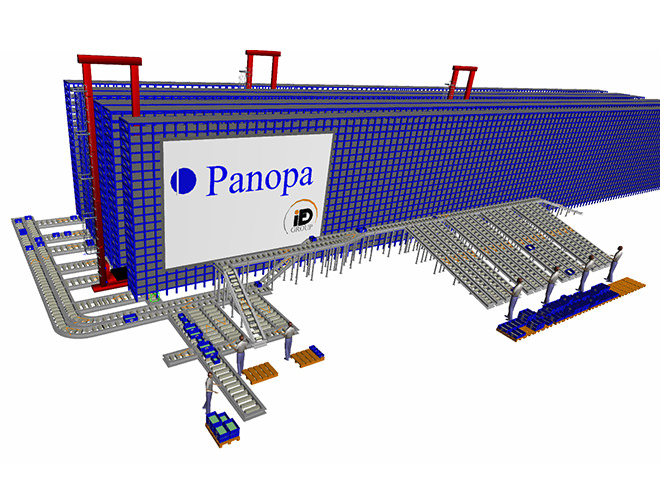

Complexity and dynamics in the production and logistics process are constantly increasing. Logistical problems often push the boundaries of Operation Research methods, and that's where our simulation system comes in. The digital model analyses emerging issues and can be fixed before they affect your inventory.

With a reliable simulation, you receive an important tool for answering questions regarding the optimal design of conveyor technology as well as for the optimization of production processes and order sequences. This allows you to check in advance the benefits of planned investments and to assess their effectiveness.

With a simulation that realistically maps the complexity and dynamics of your technical systems, your processes can be displayed transparently. You can test new processes and coordinate them optimally. The simulation shows cause-and-effect relationships and allows bottlenecks to be identified and analysed before they occur.

support level 1 – Helpdesk:

You report the incident to the helpdesk of the iFD Group. By means of a hotline and/ or remote access for application software, a first error analysis is carried out and necessary measures are initiated.

support level 2 – Second Level Support:

If a problem can not be solved by our help desk, the second level support will handle the service case.

support level 3 – Third Level Support:

In the event that the problem solving needs to involve the developers of the affected components, manufacturers or third parties, the help desk monitors and coordinates necessary activities.

After more than 15 successful years, our Head of Sales Susann Erkmann is taking a sabbatical. She will be succeeded by Jens Kreißl, who has been part of iFD GmbH for over 5 years and has contributed significantly to the success of iFD.

LogiMAT 2024 took place from March 19 to 21 under the motto "SHAPING CHANGE TOGETHER". With an impressive variety of exhibitors and innovative solutions, the trade fair offered a comprehensive insight into the latest trends and technologies in the industry.

The hidden champion igus, manufacturer of lubrication-free and wear-resistant high-performance polymers for motion ("motion plastics") based in Cologne, relies on the WarehousePilot from the material flow experts at iFD to modernize the automatic control and management of its high-bay warehouse.

For over 55 years, our new client has been developing and manufacturing innovative braking, chassis, and drive components for companies in the automotive industry. In recent years, the company has steadily evolved into a significant player in the global metal forming technology. Due to the digital transformation and to ensure continued production quality, iFD GmbH has been tasked with implementing a forklift control system.

Read more … Automotive Supplier Optimizes Material Handling Fleet with iFD-Forklift Control System

iFD to showcase cutting-edge software solutions at LogiMAT 2024

iFD is looking forward to participating in LogiMAT 2024, one of the most prestigious international trade shows for logistics and intralogistics in Europe. The event is scheduled to take place at the Stuttgart Trade Fair Centre from March 19 - 21, 2024, where iFD will be exhibiting its latest advancements of its software solutions in booth 8F80, located in hall 8.

According to the organizers, LogiMAT 2023 achieved the highest attendance since the inception of the fair, with a total of 62,343 trade visitors. This aligns with our experiences and impressions this year. Never before have we had so many appointments and interesting conversations with potential new customers as we did at this fair.

Read more … LogiMAT 2023 - A review of our annual highlight on the trade fair calendar

The International Trade Fair for Intralogistics Solutions and Process Management will take place again in Stuttgart from April 25th to 27th, 2023, and IFD GmbH will once again be represented as an exhibitor this year.

From March 20th to 23rd, 2023, one of the largest trade fairs for material handling, logistics, and supply chain in North America will take place. As a reputable software partner for the entire intralogistics industry, iFD GmbH will also be present at this year's edition of PROMAT in Chicago.