LOGI-KIT

Use Inventory Warehouse Economucally

Use Inventory Warehouse Economucally

Why LOGI-KIT?

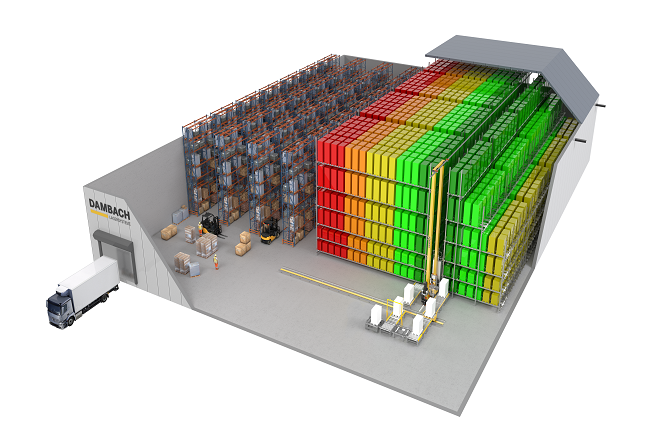

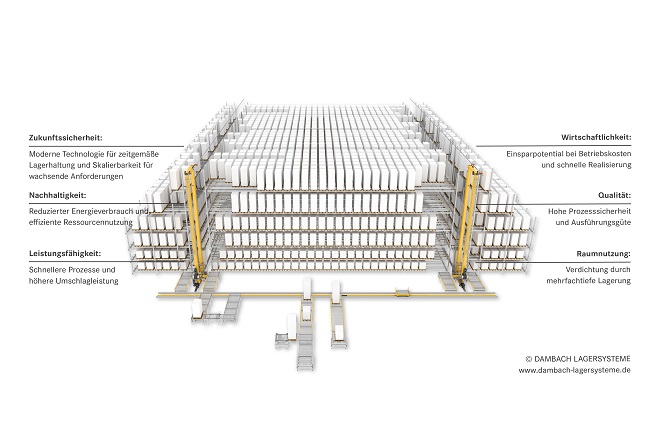

So that existing warehouses and buildings can also enjoy the advantages of automation. Warehouse operators benefit from higher storage space density, greater throughput with lower personnel requirements and thus lower operating costs. With LOGI-KIT, forklift-operated pallet warehouses can be subsequently automated: whether narrow-aisle warehouses for manufacturing companies or wide-aisle warehouses for contract logisticians - LOGI-KIT meets individual requirements with its flexible ZERO and INFINITY versions. The fully automatic system can be adapted to spatial restrictions. In addition, picking stations, storage capacity and pallet handling performance are scalable.

Benefits of LOGI-KIT:

LOGI-KIT is a product of DAMBACH Lagersysteme GmbH & Co. KG and is therefore based on more than 45 years of experience in the field of automatic storage technology. In addition to the storage and conveyor systems, LOGI-KIT can also be smoothly and seamlessly integrated into the existing IT environment. Interfaces to different ERP (Enterprise Resource Planning) and WMS (Warehouse Management System) are easily possible.

The IFD Material Flow Calculator Plus offers an economical software solution. This can be modularly expanded to include specific WMS functions, such as storage space management and picking strategies. For uncomplicated and successful automation, LOGI-KIT offers everything from a single source: advice, analysis, planning, storage technology, software, project coordination and implementation. On request, support with financing with leasing partner

|

|

|

See for yourself With LOGI-KIT INFINITY, the storage space capacity in existing warehouses can be increased by up to 100% through the use of shuttle systems and channel storage. The result is an extremely compact and automated warehouse. If the performance is to be increased, LOGI-KIT ZERO is the right choice. Through the use of automatic storage and retrieval devices with swiveling or telescopic forks, the system performance can be increased many times over compared to manually operated warehouses. Existing shelves can also be reused and expanded with additional rows of shelves. Even floor-to-ceiling pick-up and delivery of pallets is possible. With iFD GmbH, LOGI-KIT has the perfect partner to harmonize the requirements of an automatic storage system and the existing IT infrastructure. The digitization of the material flow and autonomous control of the storage process make transparency, traceability and the "Internet of Things" (IoT) a reality. You don't have to be an automation professional to benefit from modern automatic warehousing - LOGI-KIT offers easy-to-integrate automation solutions for future-proof warehousing. |